|

After scrounging a Hot Tub, my son Garrett figured he deserves and I should pass on to him the title of Top Scrounge Who holds the title is not as important to me as the fact that a landfill site

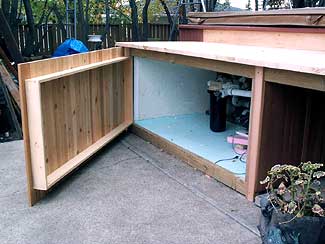

July 15, 2001 Finally, something that my wife agrees is not junk! A month after our son Garrett (center) scrounged this hot tub he bought a house and Mom is OK with him moving out, BUT she made it clear that the Hot Tub Stays! When Garrett over heard someone mention how much it was going to cost to have his old hot tub hauled to the dump he quickly introduced himself and enquired why the tub was being scrapped. The owner said he got tired of replacing a motor control switch that kept burning out and had purchased a new tub. Garrett figured this was a fairly simple problem to solve so quickly offered to haul the old hot tub away for free. Remember the saying "if it sounds too good to be true - it probably is"? I figured this hot tub may turn out to be an example of this (which it did), but we had nothing to loose and considering what a new hot tub cost one could afford to spend a few dollars on repairs and still end up with a great deal. Like most hot tubs, the bottom must be properly supported for the tub to withstand the weight of all the water, however it was obvious that this had not been done and that the outside edges of the four walls had been supporting a lot of the weight as there were a number of stress cracks around the upper portion of the side walls which leaked. It was also obvious that the water heater had failed when the outside temperature was below freezing and that no one had noticed in time to prevent the water from freezing as a number of the fittings had been damaged and leaked from this happening, but a little fiberglass work repaired the leaking cracks and a little ingenuity fixed the leaking fittings. Anyone that knows Garrett and myself knows we would have replaced the simple thermal control switch with a fancy programmable electronic temperature control, which we did with one that had been scrounged of course, and a few hundred dollars for repair materials was still a pretty good deal for a tub costing $6,000 to $8,000 new. |

|

||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||

|